Because the above dynamo, mounted to my engine, was originally from a XK120 I needed to look for the correct one.

This dynamo has a brass identification plate with the following information:

Lucas 22452B, GC51, C45PVS/5, 12V, 53

The dynamo I needed should have the following numbers:

Lucas ,22462B, GC51, C45PVS/5, 12V, 56

An other XK140 restorer in my neighborhood offered me a deal I couldn’t refused.

Exchange mine xk120 dynamo for a correct, fully restored, xk140 dynamo and give him a small reimbursement for the parts he used for the restoration.

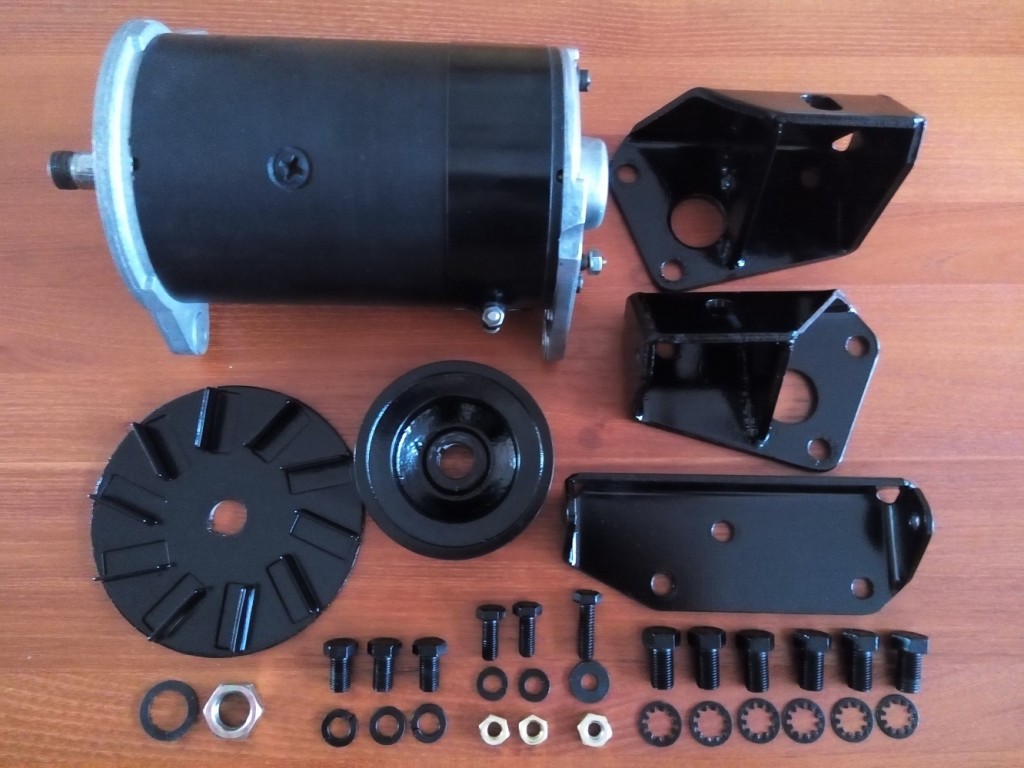

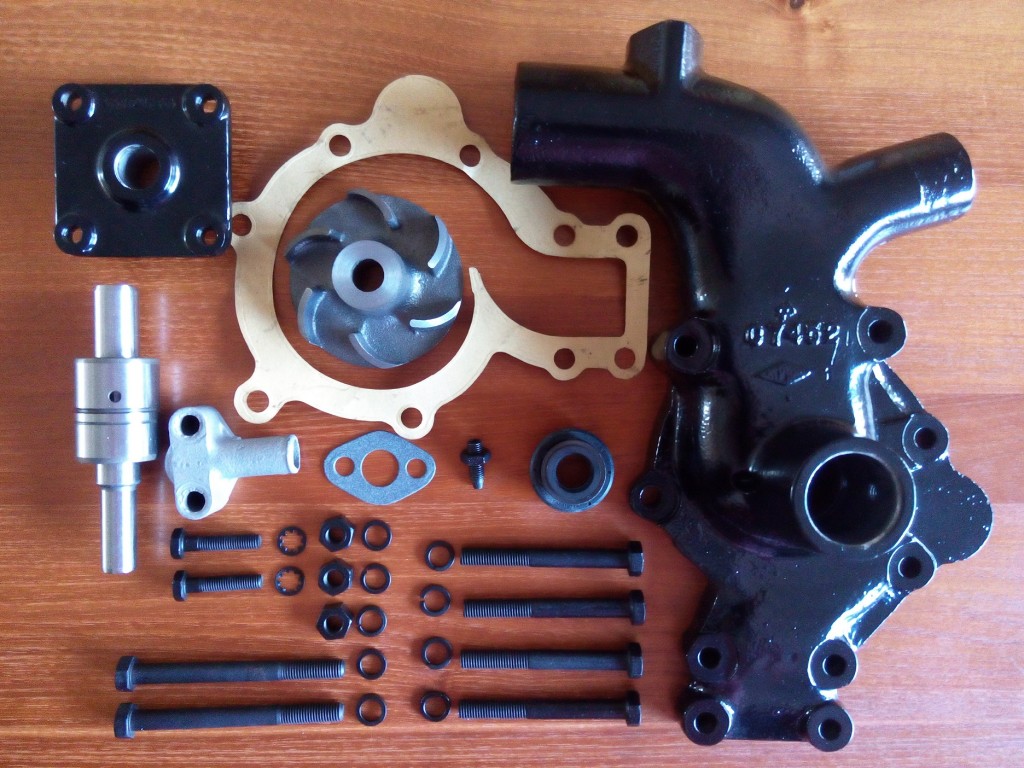

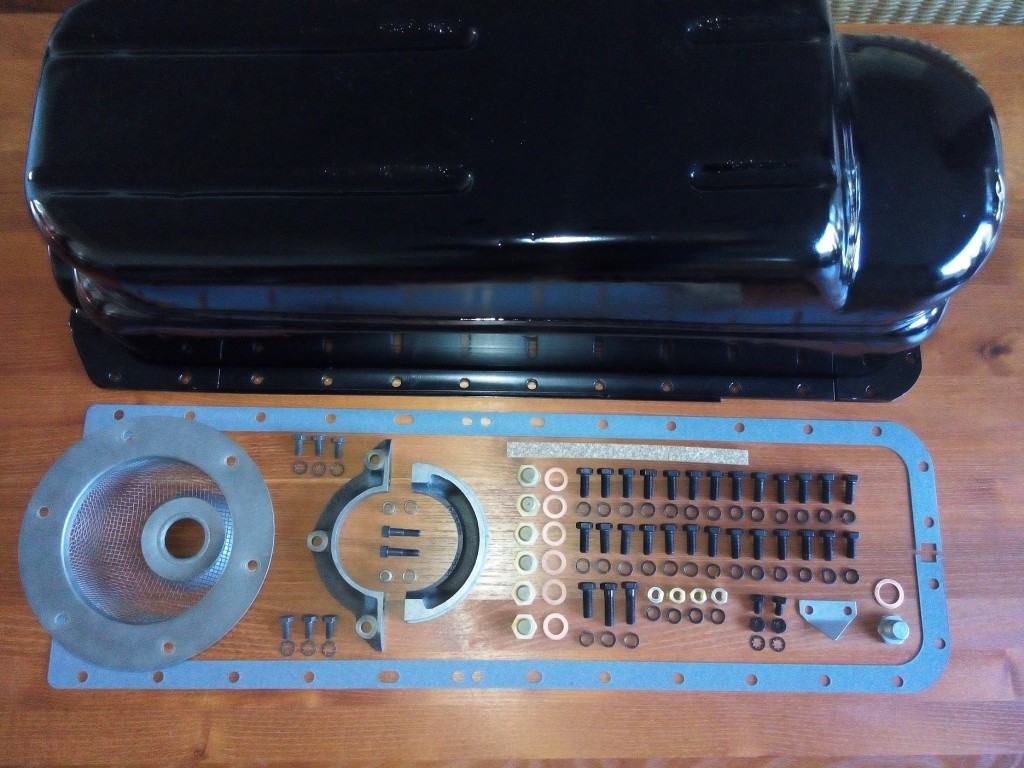

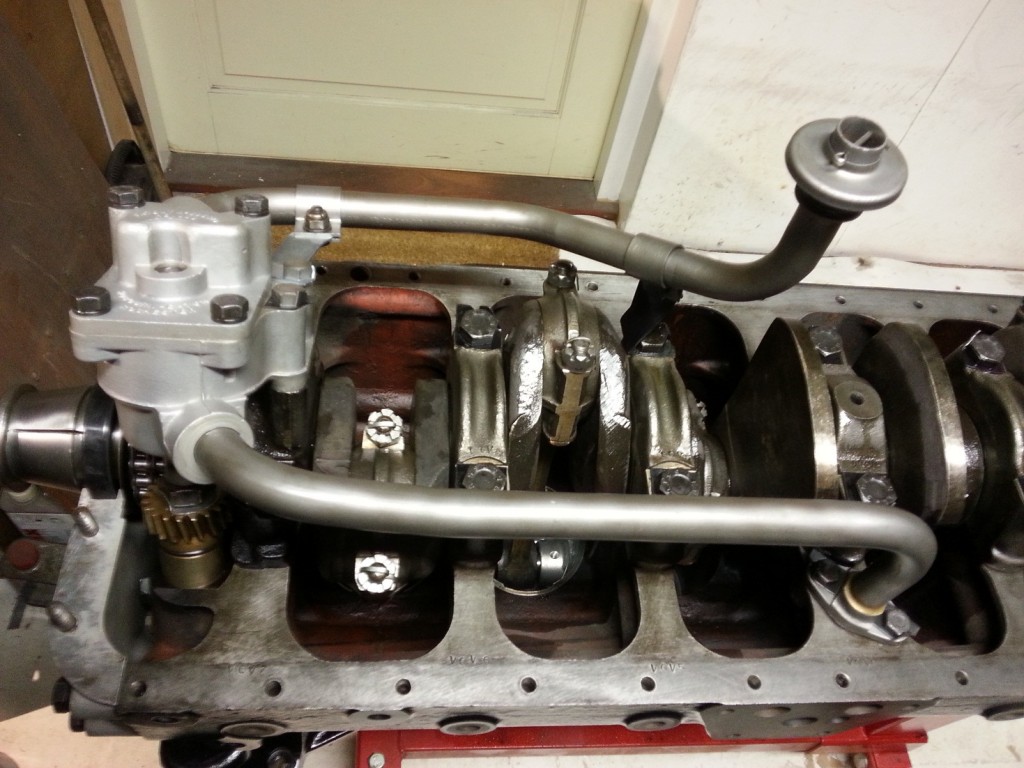

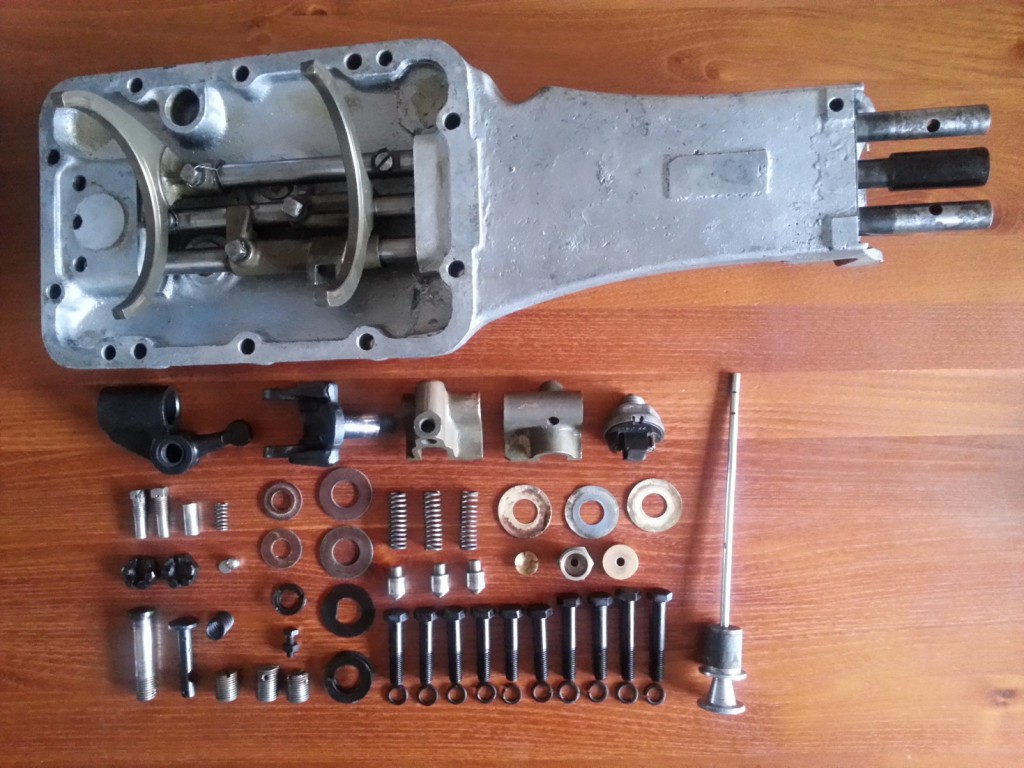

All separate parts are again sandblasted and pained black so they all look again as new.

To prevent rust, and make it easier to remove them in the future, the bolts are also painted black and mounted with a little bit tectyle.