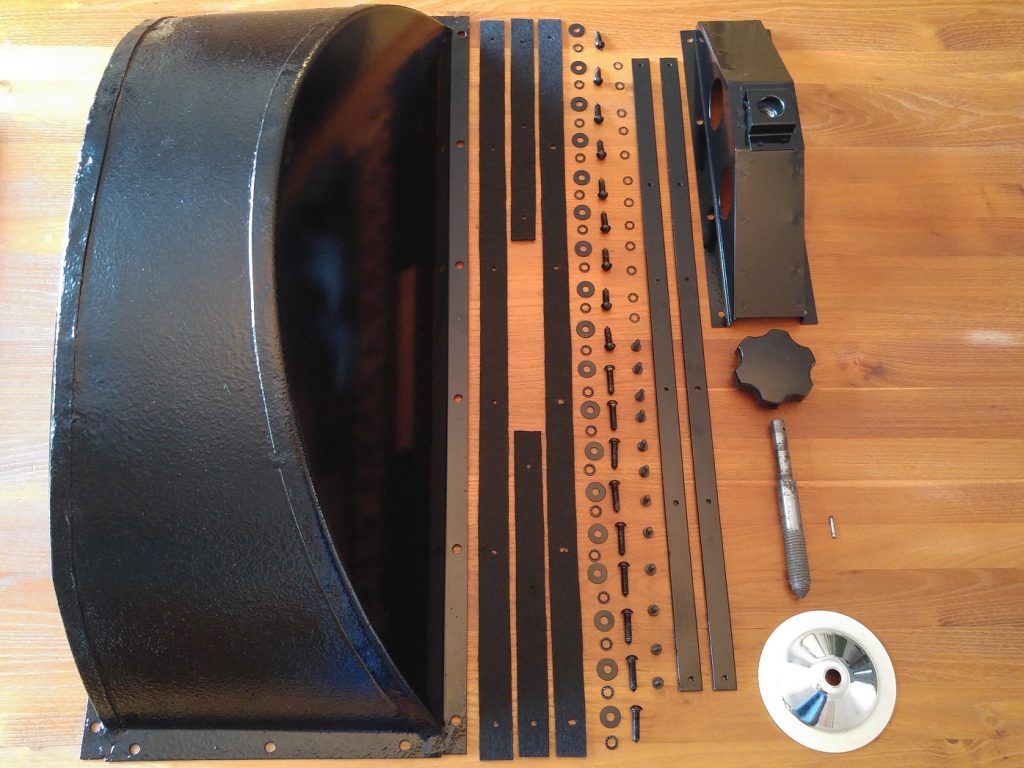

When I bought the car 8 years ago the body was already removed from the chassis. Today they will be reunited again. The chassis was already ready and the body has been finished on the underside in the past few weeks.

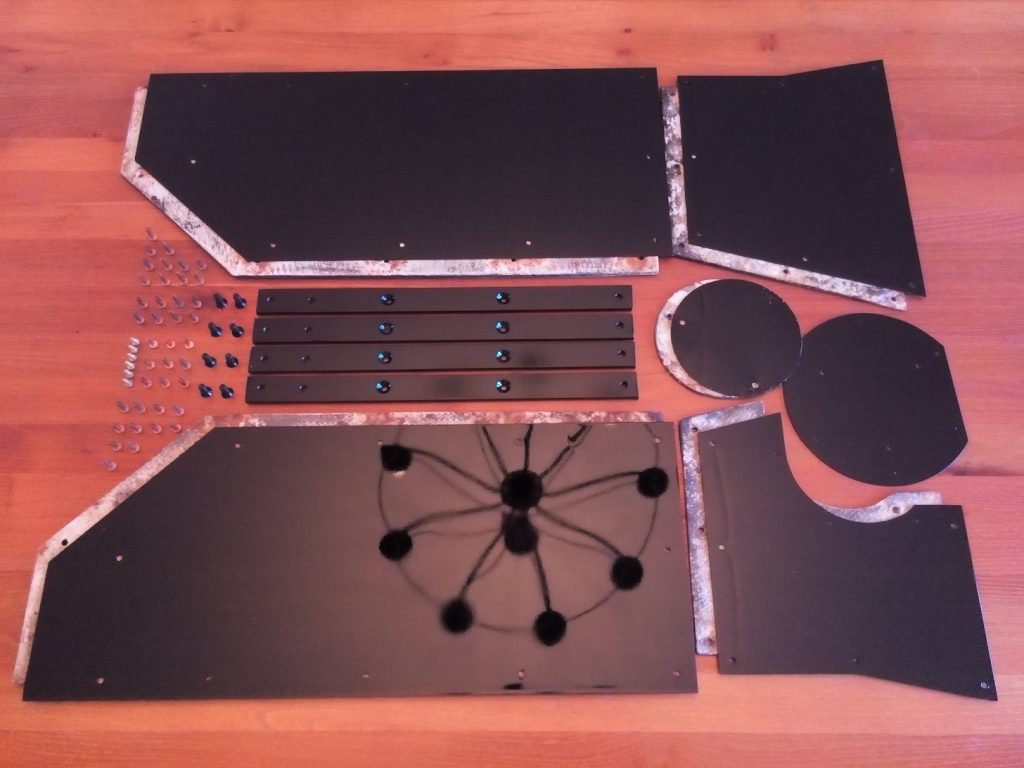

The previous owner has kept a good administration of where all the distance pieces originally belong.

It is very important that they will be placed back on the exact same place.

This car has 18 places where the body will be mounted unto the chassis;

- 4 on the Front Wing Support (2 on each side)

- 4 on the fixed floor (short bolts, with square aluminium distance pieces)

- 4 on the door sill (medium bolts, with round distance pieces)

- 2 nearby rear chock absorber (pointed bolts, with round distance pieces)

- 4 on the rear end of the body (large bolts, with round distance pieces)