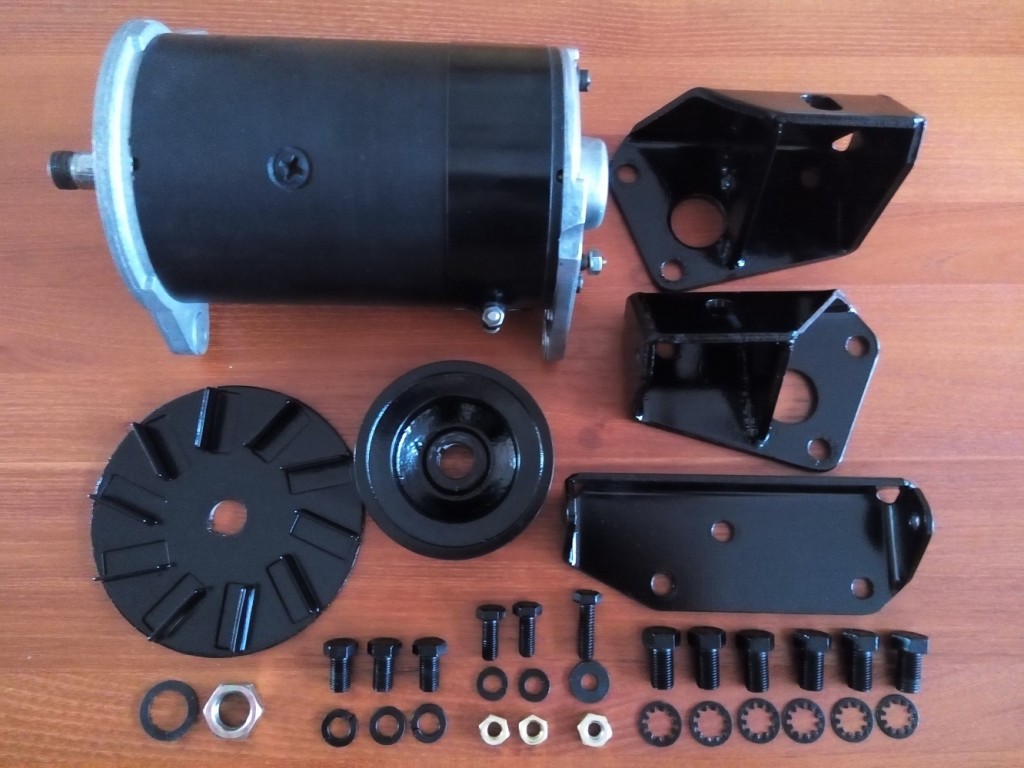

Front side of the engine with wrong fan blade

Originally the engine inside my car was equipped with the wrong type of fan blade. Instead of the xk140 type blade (symetric) it was equipped with the xk120 fan blade (a-symatric)

With the fan blade mounted the front of the engine is now almost finished. Only the cylinder head is missing, which is still at the machinery.

It is not completely clear if the aluminium blades should be painted black or not, the documentation is not very consistent. Most original pictures/photos show the bare aluminium without any paint.