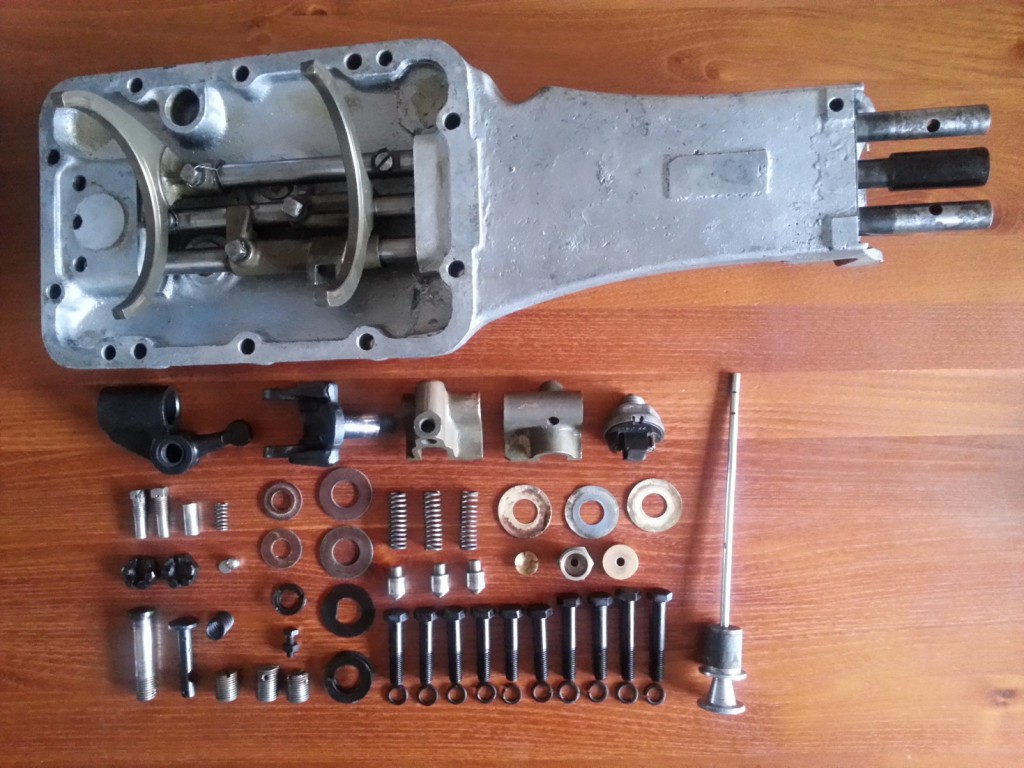

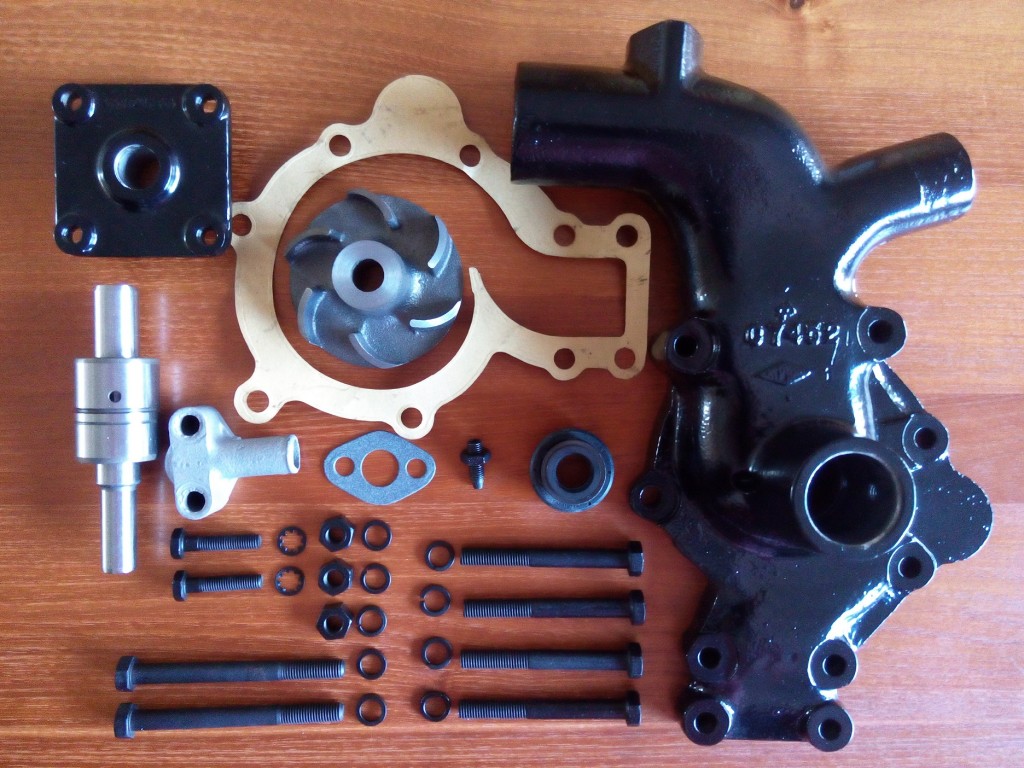

The last part needed to complete the gearbox / bell housing is the striking gear. The part makes the translation from movement of the gear stick to selecting the correct gears inside the gearbox.

The Xk140 has the normal H shape for 1st, 2nd, 3th and 4th gear. The reverse gear is placed on the left side of the 1st gear. Before the reverse gear can be selected the gear stick must be pressed to the left with a little pressure before it can be moved forward.

A fresh gasket will be use to mount the assembled striking gear on top of the gearbox.

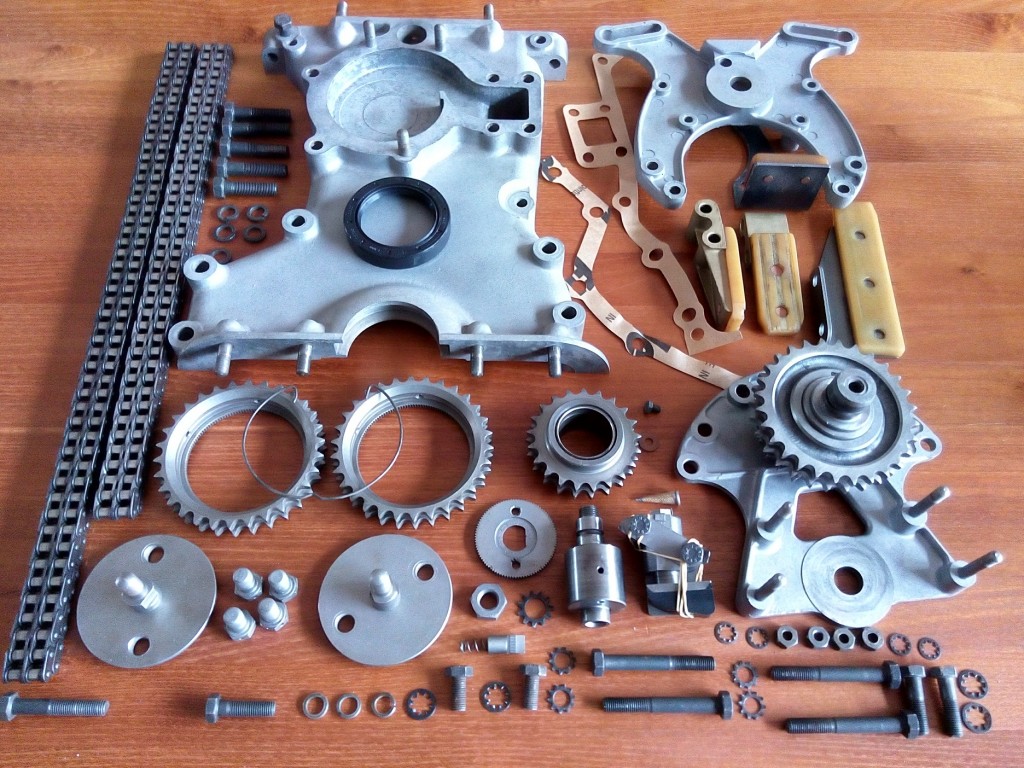

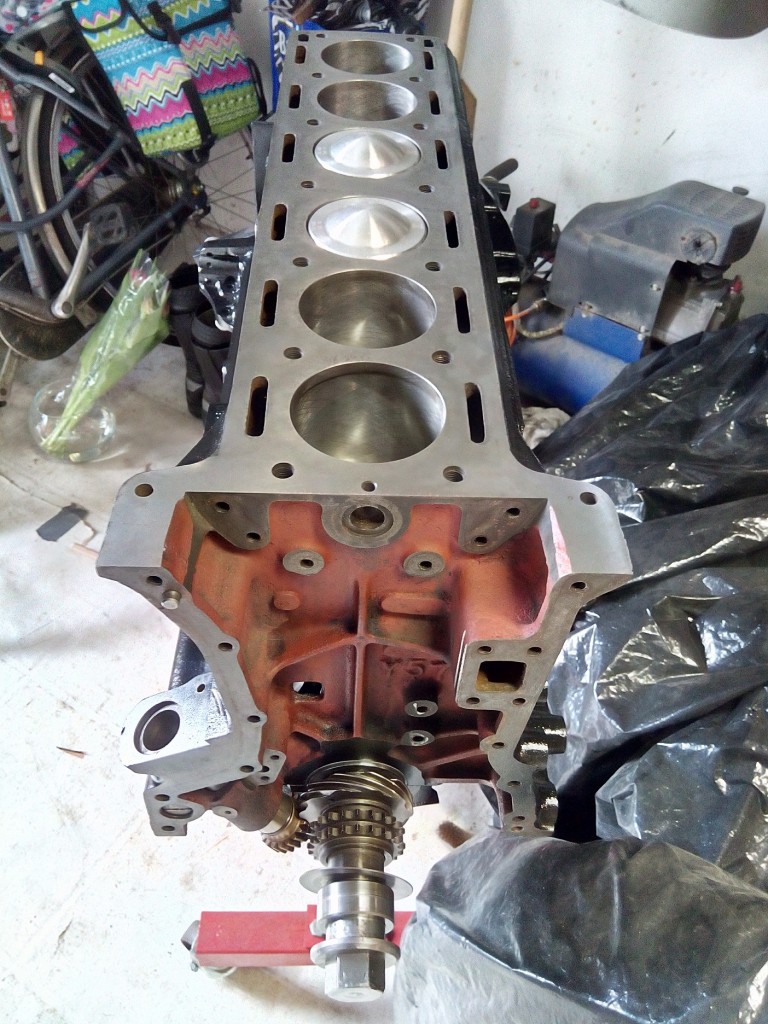

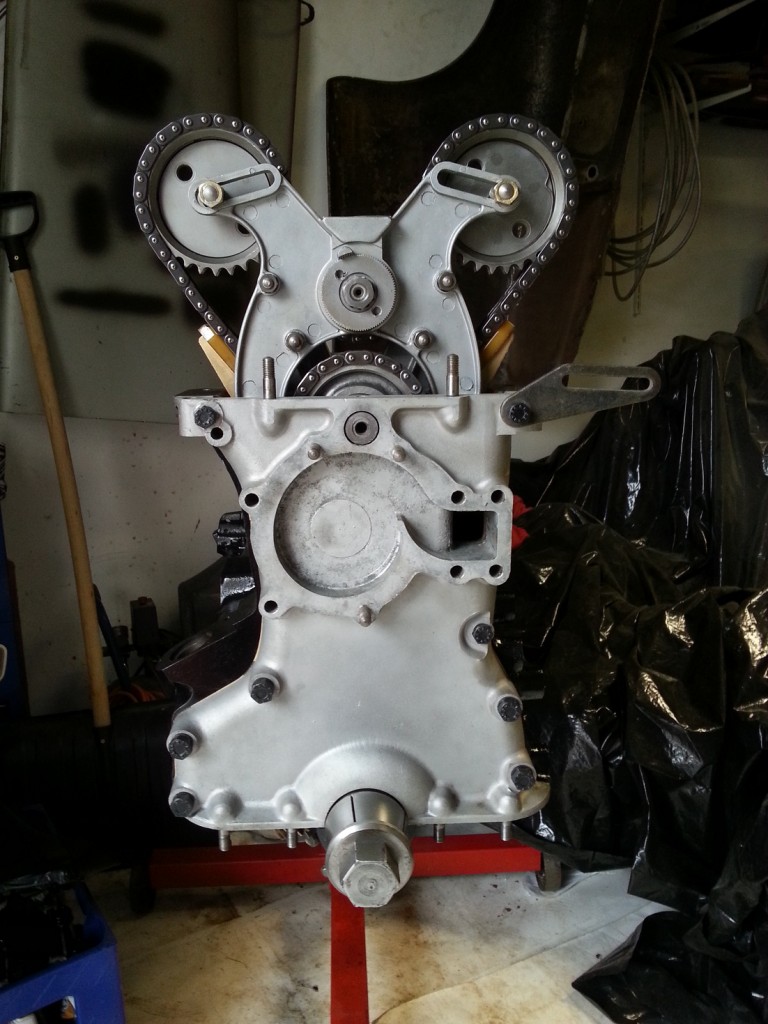

Now everything for the gearbox and bell housing has been finished we can start assembling the engine.