The fairing panel, the connection between the two front wings, has been removed completely because the front wings were also removed. This piece already shown some cracks on the places where is was welded onto the front wings. Now the front wings are remounted again the fairing panel, after it has been repaired, can also be put back again. To smooth out the surface a layer of lead has been applied, to prevent a tick layer of filler during the paint job.

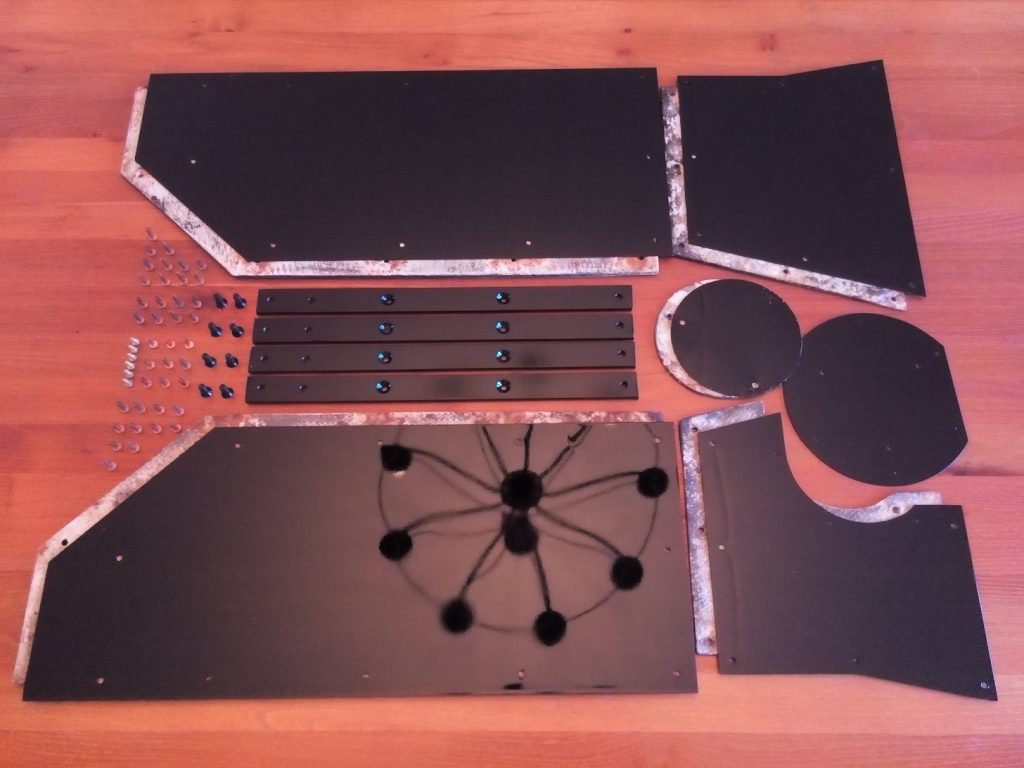

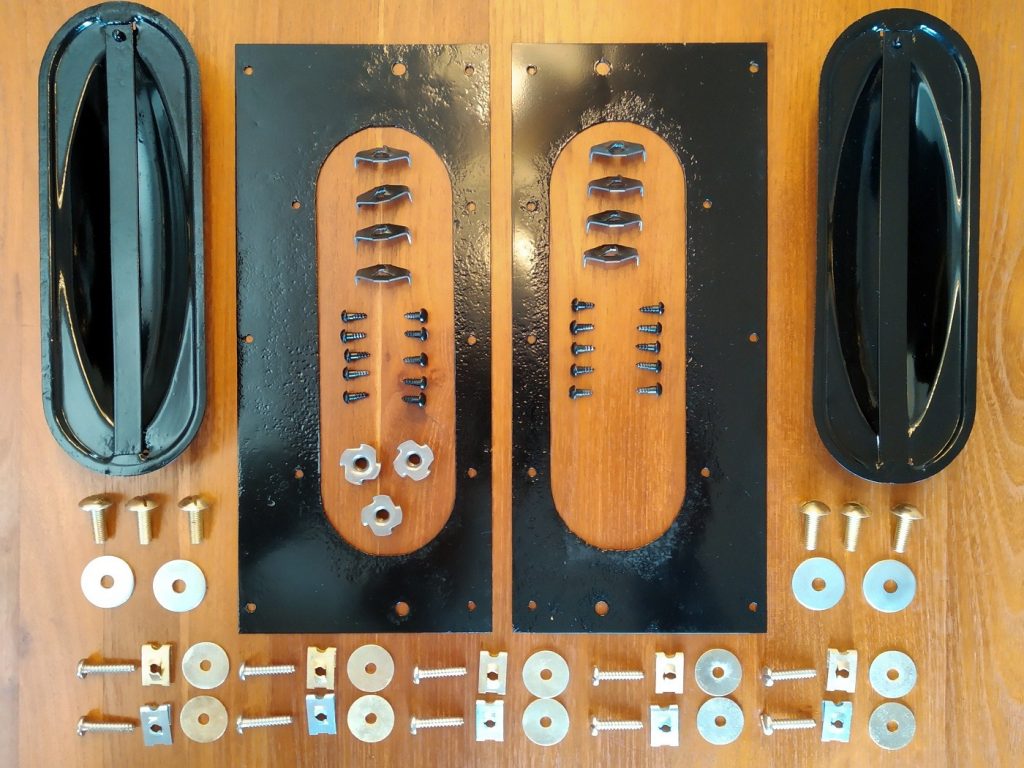

When I bought the car the original wooden floor boards where not available anymore. The openings where closed with a very thin piece of cheap plywood. All needed mounting material was also not available anymore.

I was able to borrow an original left and right side floorboard. With the help of these floorboards i was able to buy all missing parts. I also uses them as template for the new floorboards.

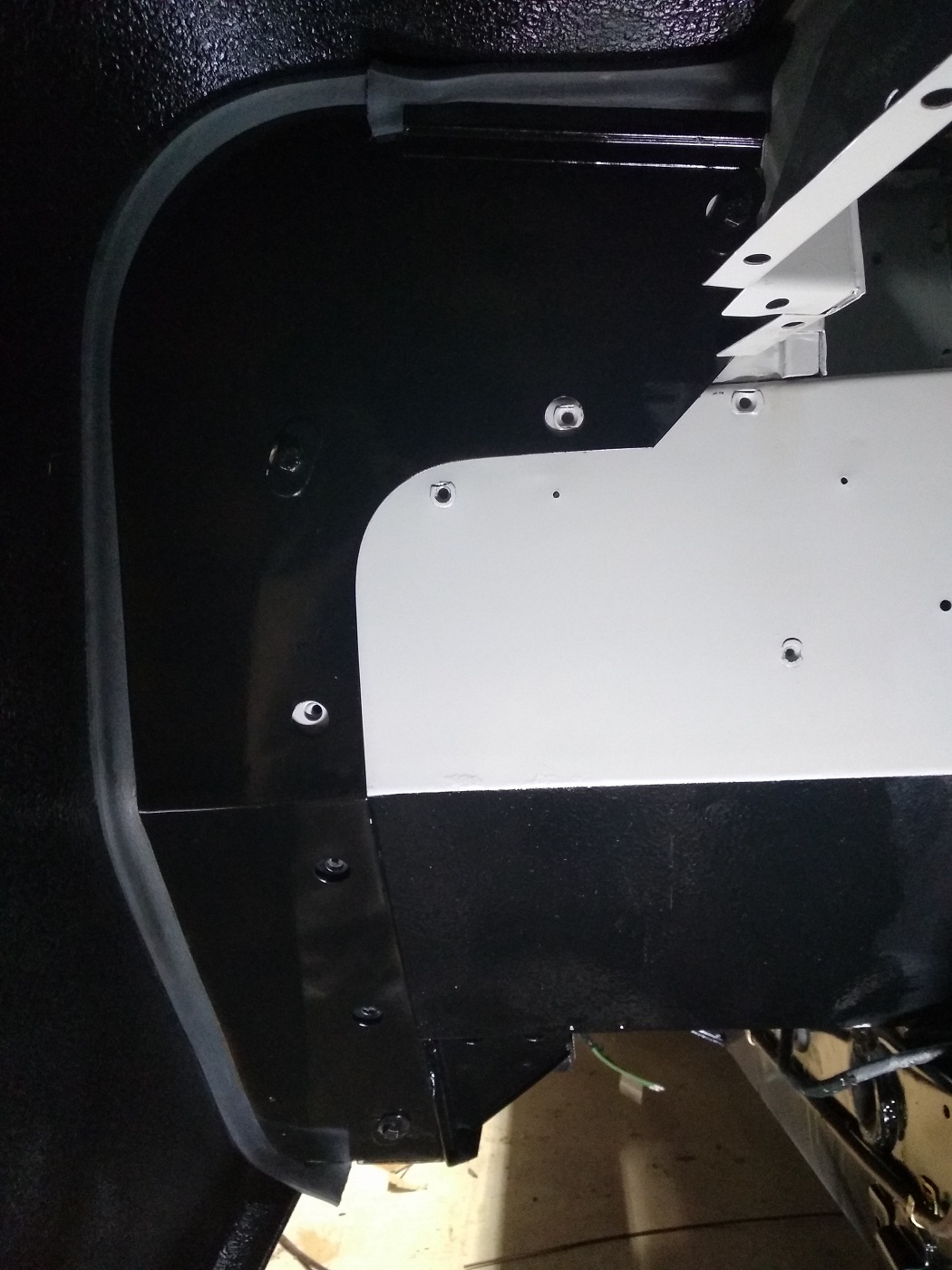

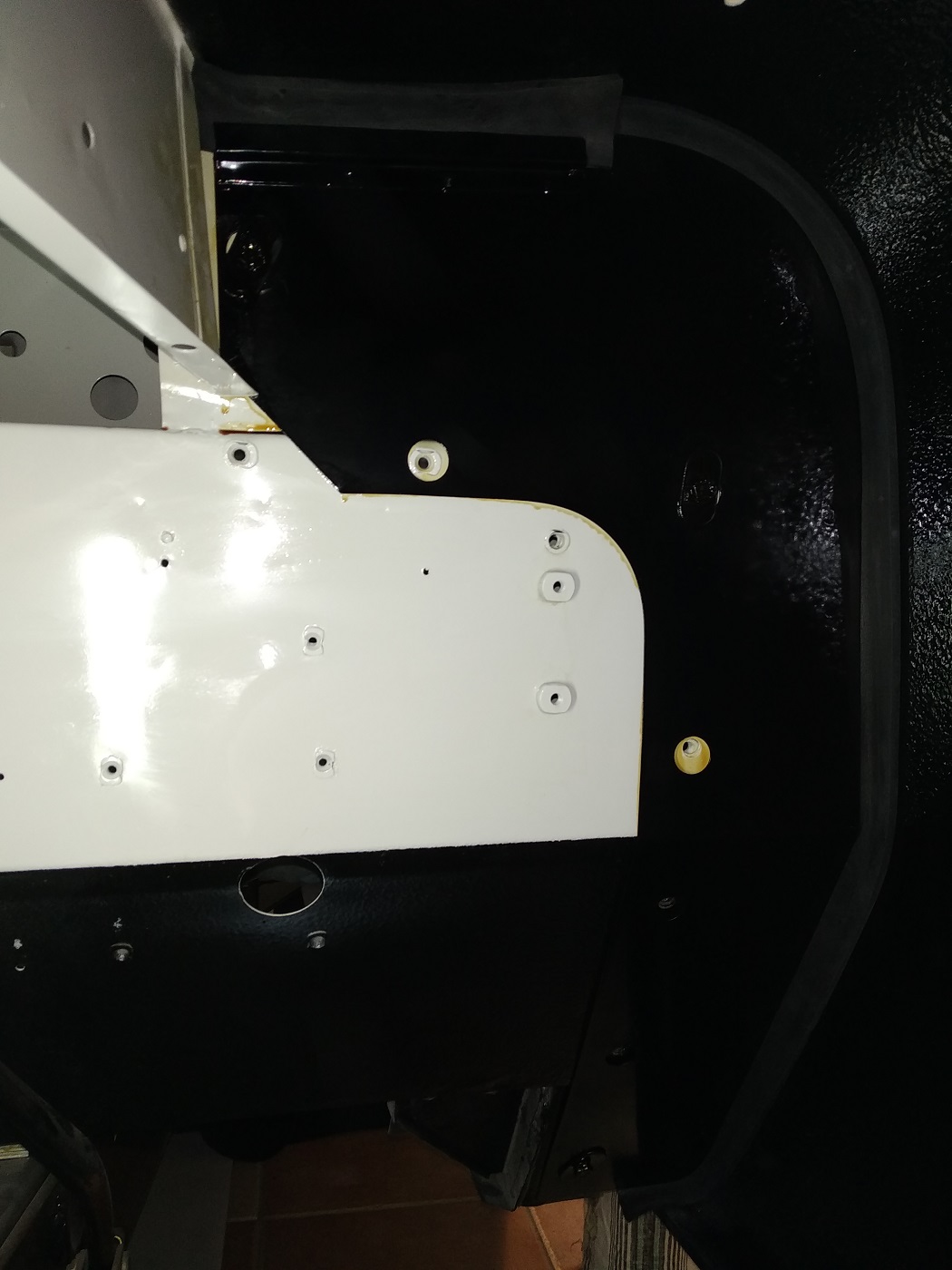

Now the left and right front wings are restored, and the inside has been painted, it is time to place them back onto the body. Although most restorers leave them onto the body en remove the lower part of the front wings to repair the dashside strengtheners, I decided to remove the whole front wings at the place the where originally fixed to the body.

This method has the following advantages/disadvantages:

- + Removing and mounting can be done by myself.

- + Cleaning the inside of the front wings is much easier.

- + Repair and cleaning of the dashside strengtheners is very easy

- + Afterwards it will be invisible to see they where removed.

- + During the restoration process it was easier to store them temporarily in the attic.

- – Difficult to place the wings back on exact the same spot.

- – Lead must be placed back, which can be difficult.

The front wings are welded to the body nearby the front windscreen. Nearby the radiator the front wings are mounted on three places with bolts onto the chassis.

Now that the front wings are mounted and the front hood is placed, it starts to get the contours of a Jaguar xk140 again.

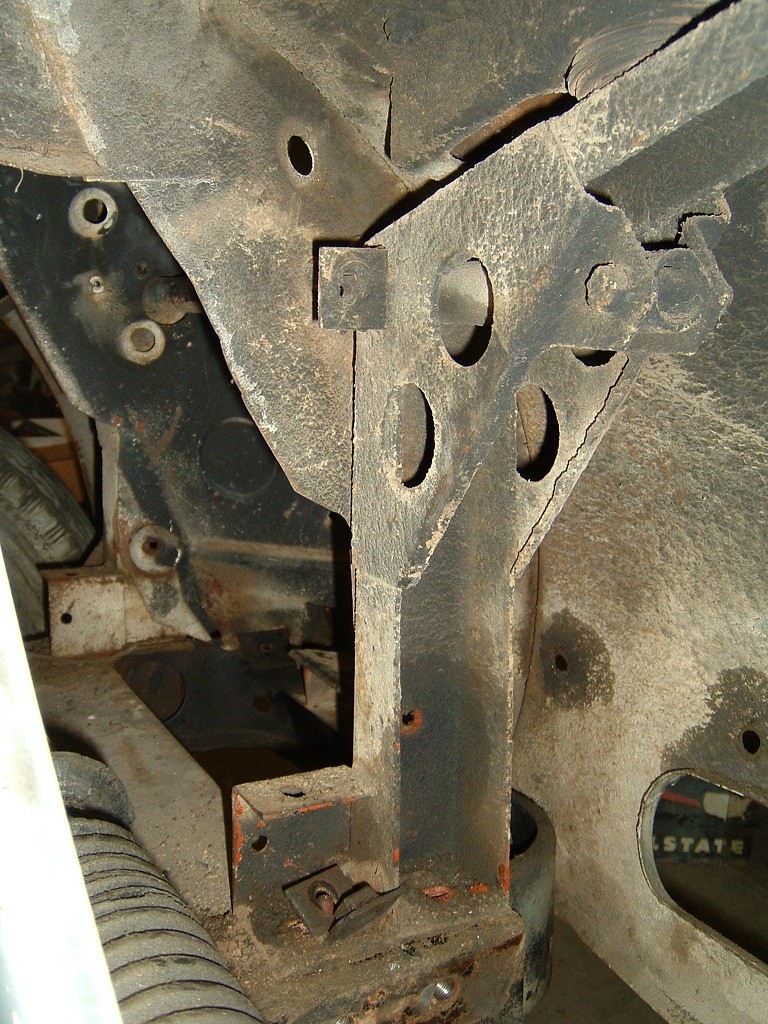

The front wing supports are used for the following purposes;

- Keeps the the front wings on the right place in front og the car

- Mounting of the radiator

The front wing supports are only painted in some sort of orange undercoat, as can be seen on the original photo above. The complete body was leveled out in the factory with aluminium or plastic(kautex) distance pieces. (See dish shaped parts in the next photo)

On the right side we also have to mount two mounting brackets which are used for fixing the distributor shield.

The tie bar which connect the two front wing supports with each other must be removed when the front wings are mounted. The tie bar is running through the front wings and there must be mounted when bot front wings are in place. (See original photo)

The car originally arrived with an automatic gearbox which is useless with a manual gearbox. Also the gearbox shift cover was missing. I spend a long time looking for one on the internet but when they van be found they are very expensive. To keep the car so authentic as possible the plastic variant are not an option. So I decided to create a Gearbox Cover myself.

To prevent that the heat from the outlet will heat up the floor, heat shields are provided on the underside. The heat shields are made from asbestos and are covered by a thin layer of aluminium to prevent the asbestos from crumbling. These aluminium asbestos protection plates where corroded and need to be replaced by new ones. The asbestos shields are still in good usable condition and will be reused.

Because the rivets, used to mount the asbestos and aluminium sheets to the steel floor, can only be used one-time I started to search for them on the internet. After some time I discovered a bunch of brand new, by Jaguar so called, “Bifurcated Rivets”

One of the last big metal work pieces are the front wings. After the left front wing was cleaned thoroughly the following repairs need to be done before the wing can be painted inside.

- The valance assembly has several holes of 1″” drilled for some unknown reason.

- Headlight pod has extensive rust in the under side of the headlight mounting area.

- The lower edge of the front side has a small hole due to rust (about 2″ by 1/4″)

- The steady bracket which mount to the battery box has some rust

- Dents in the area around the flashing light (due to badly repair after a collision in the past)

Cleaning the inside

The inside of the wings are protected with a very tick layer of tar which protected the inside from rust.

From the photo it is clearly visible that it did his you very well. The right side, the part behind the mud shield, which was not protected is much more affected by rust.

After the layer of tar was removed with a small torch and a putty knife the undamaged metal became visible.

When the whole surface was cleaned with a poly-carbide steel brush the front wing looks like new again. All difficult to reach area’s are now sandblasted so the inside is now ready to receive the first layer of epoxy primer.

Headlight pod

Due to long lasting condensation inside the headlight pod the lower part has been damaged by extensive rust. First the lead, used to smooth up the connection between headlight pod and front wing, is removed. Now all by rust affected material is removed and the holes in the front wing are welded. Now we know how much material is missing we can start with producing the new pieces.

The new pieces are fitted for the last time and welded unto the headlight pod. The last step is reapply the lead to smooth out connection between the wing and headlight pod.

When I was investigating the headlight pod from the right side front wing (which is not rusted at all) i found a small hole in the lowest part. My first impression was that there was a small hole due to rust but after looking in more detail to the inside area it looks like a small hole to drain water. I will make such a hole in the left headlight pod as well.

The valance assembly

The holes in the left front valance, which are certainly not original, needs to be removed. In total 9 holes where drilled. With this amount of holes it is better to just remove the hole affected area as one piece and remove it for a new piece.

Painting

The inside inclusive the valance will be painted in the following order:

- Epoxy primer

- Body schutz (Protective coating helps protect from corrosion and chips)

- The inside will be painted satin gloss

- The following parts are painted in Pearl grey

- Valance assembly (both sides)

- Headlamp light unit container (inside)

- Side lamps casing (inside)

Repair

The left rear wing has two attention areas;

- The lower edge at the door side

- The upper part also at the door side

Cleaning

Now that the rear wing has been repaired the thin layer of rust can be easily removed with a wire brush and sand paper.

Painting

Now that the inside is nicely shining again the following activities can take place;

- Apply a fresh layer of Epoxy primer.

- Make sure all seals are seamed. (3M Heavy Drip-Chek Sealer)

- Apply a protective layer to prevent chipping. (3M Textured Anti-chip Coating)

- Last but not least a layer of satin black paint to make it easier to clean the inside.

The lower body side was partly covered with dirt and undercoating. The undercoating had already been released in many places and must be removed completely to be able to remove all rust.

Now all rust in the above picture must be removed. With the help of some chemicals and steel brushes the job was finished successfully.

Now the fun part could start, spraying the underside body with Epoxy primer. But before the spraying could start we finished the whole surface with sand paper, en just before spraying removed all dust with thinner.

The protect the body of the car Jaguar designed a mud shield which was mounted just behind the battery box to prevent water and dirt entering the car via this way.

The space between the inner front wing and the mud shield is sealed of with a rubber strip. On the photo above the mounting mechanism for the rubber strip can been seen on both sides of the mud shield