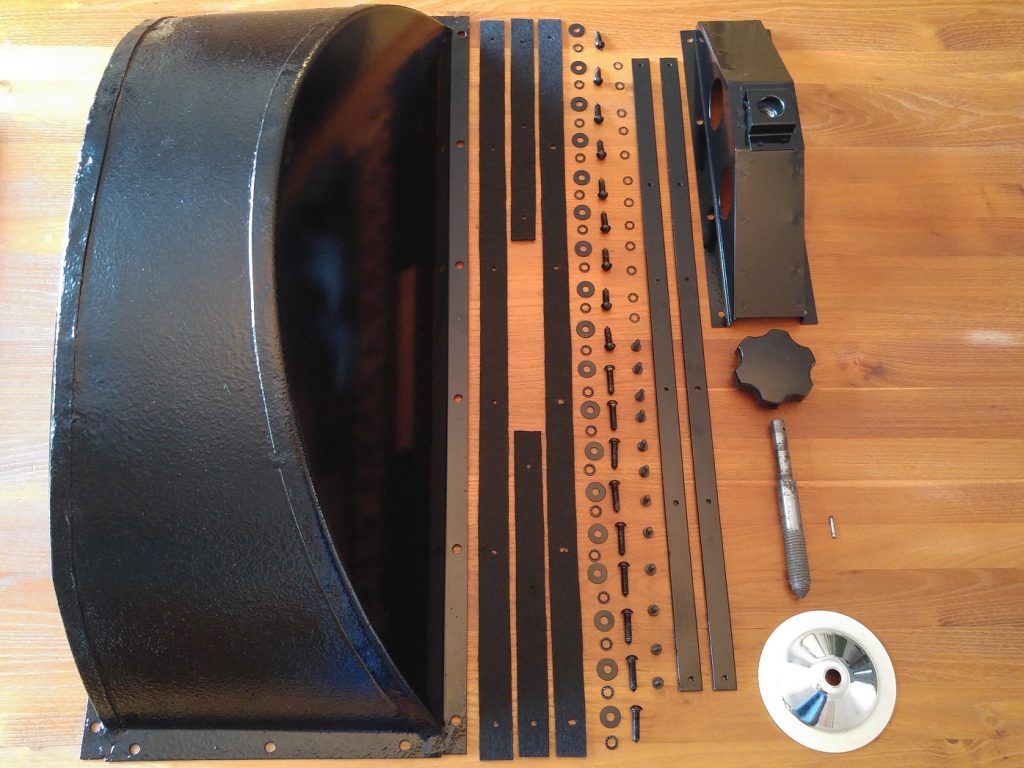

The radiator was, together with many more parts, not present with the car. During the last 6 years I was able to buy two radiators, (C9616) together with the corresponding cowl (C7651) The first radiator has considerable damage in the top and bottom parts. The second radiator misses the mounting studs on both sides.

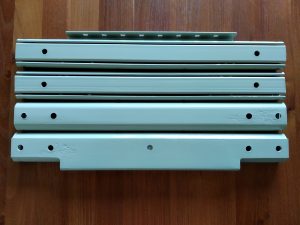

One of the two original radiators

I have to combine parts from both radiators to be able to make one nice one.

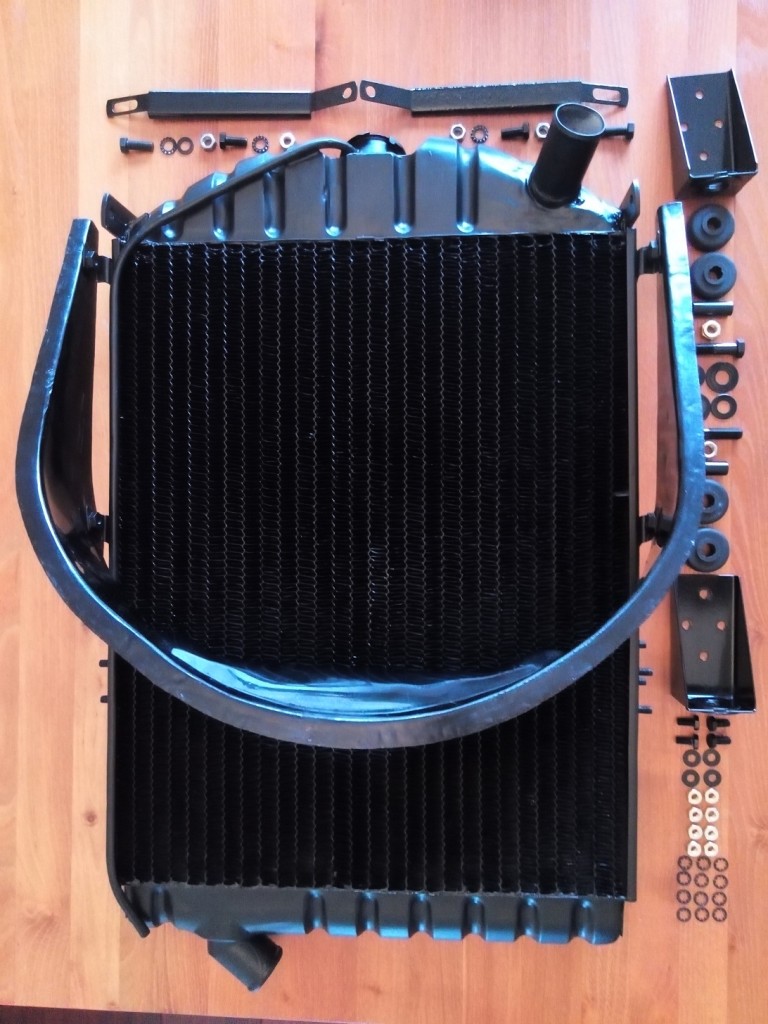

First I started with removing the left and right side (where the stud are in) on both radiators. Now, due to the fact that the good radiator has still some dents in the upper part, I also removed that part. From the inside all dents are cautious removed and soldered back onto the radiator core. The thin metal reinforcement soldered to the left side of the core must also be replace, due to rust, with a fresh new one. Now the left and right sides can be soldered back onto the radiator. Last be not least I tried to realign and straighten all fins, to improve the cooling capacity. After the radiator was thoroughly cleaned it can be painted in two layer of paint (epoxy primer and satin black paint)

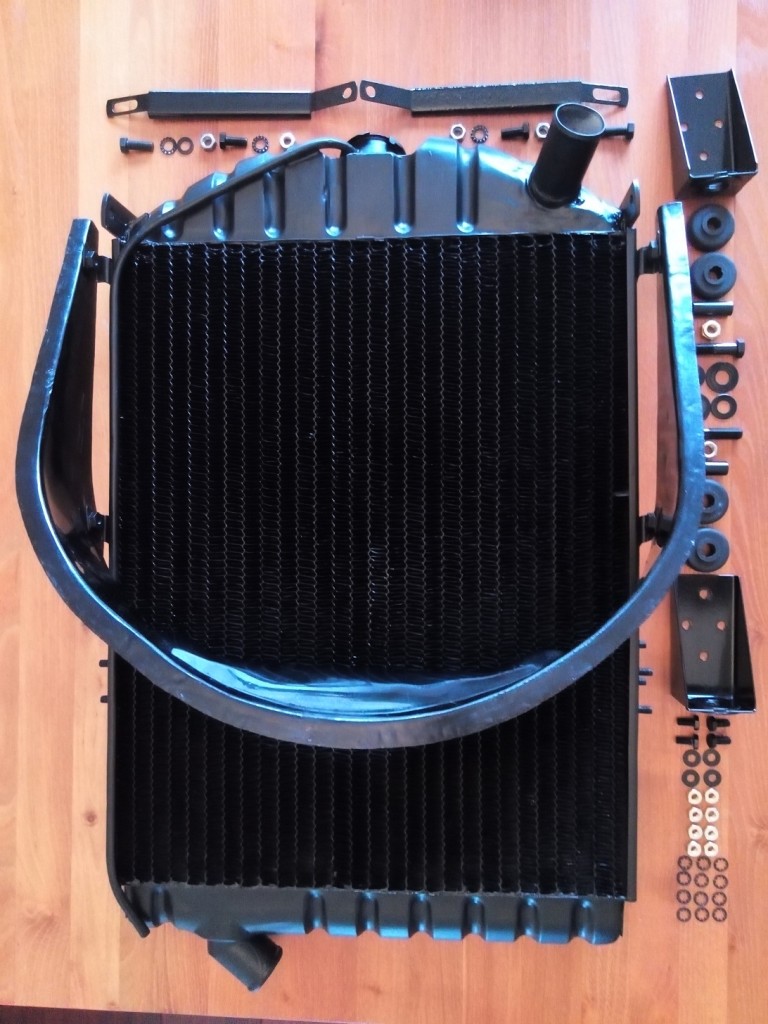

Parts needed to mount the fresh painted radiator

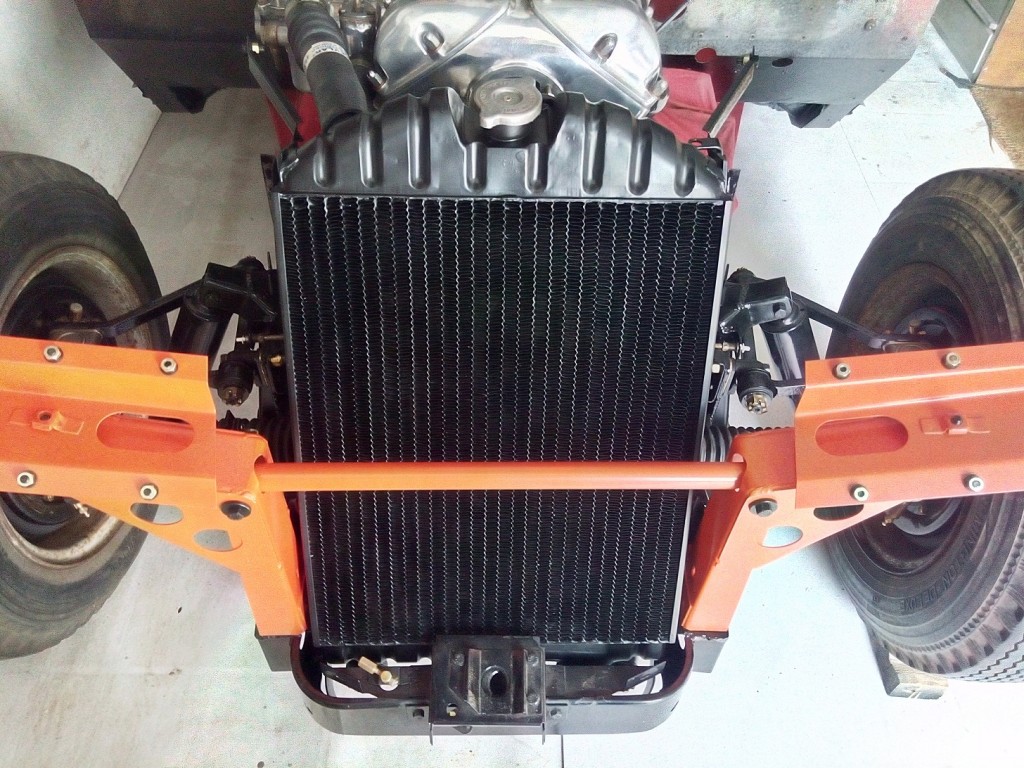

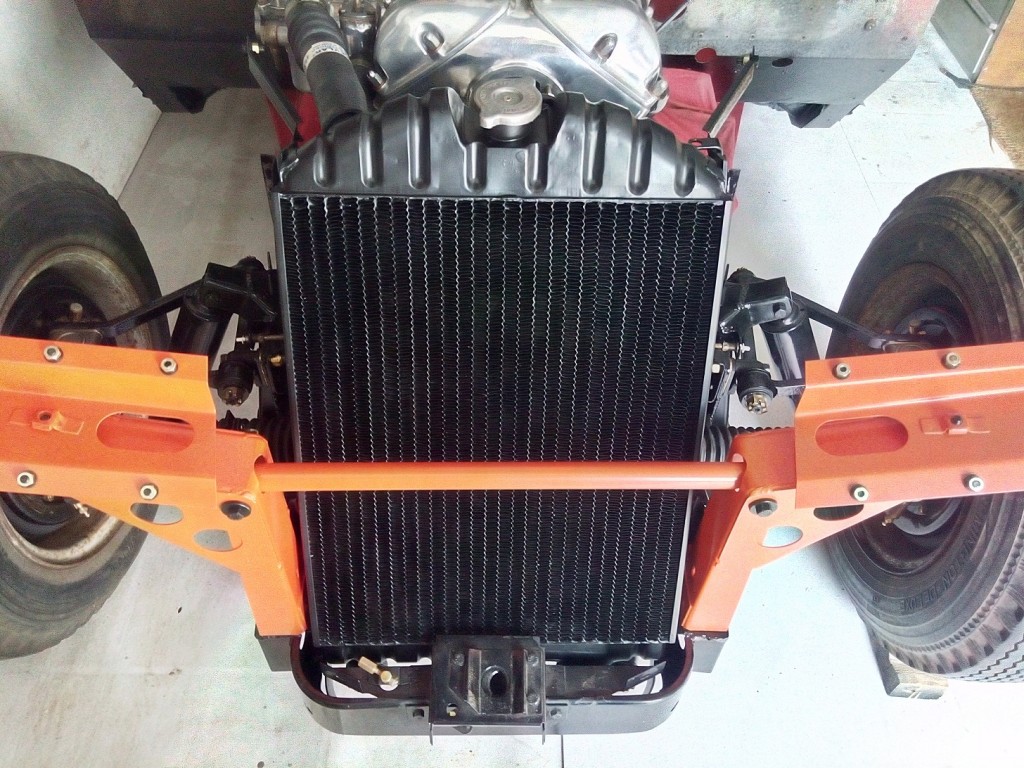

The almost as new radiator fitted as a clove between the two new mounted front wing supports.

The radiator mounted onto the car