The lower body side was partly covered with dirt and undercoating. The undercoating had already been released in many places and must be removed completely to be able to remove all rust.

Dirt and undercoating removed

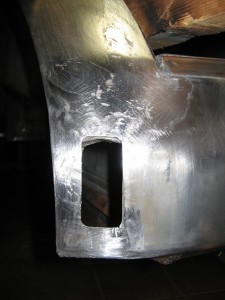

Now all rust in the above picture must be removed. With the help of some chemicals and steel brushes the job was finished successfully.

All rust on the bottom side removed

Now the fun part could start, spraying the underside body with Epoxy primer. But before the spraying could start we finished the whole surface with sand paper, en just before spraying removed all dust with thinner.

After the epoxy primer is thoroughly dried all seams are filled with 3M seal-kit. This kit, the small black lines in the above right picture, will creep between the different layers of sheet metal. When the procedure is performed on both sides the space between different layers of sheet-metal will be hermetically sealed. So hopefully no rust anymore 🙂

The last process step is adding a thick layer of anti chipping material and last but not least two layers of black paint. The last layer of paint will make it more easily to remove dirt from the underside in the near future.